AIR Inc. can provide solutions and services for all of your dust collection and emission control needs. With over 40 years of industry experience AIR Inc. has gained expertise in several industries and processes.

Some services that AIR Inc. can provide are:

Turn Key Project Installations

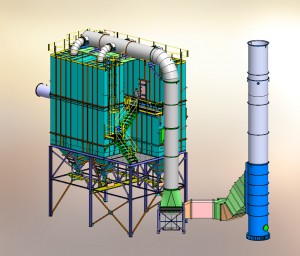

Turn key projects are our core business. As part of the “womb to tomb” service we provide, we will work the customer to ensure they are purchasing the proper equipment for their needs. From the design stage, to the installation stage, to the system start up stage and beyond, AIR Inc. works hard to ensure that the baghouse works smoothly and effectively for the customer.

Turn key projects are our core business. As part of the “womb to tomb” service we provide, we will work the customer to ensure they are purchasing the proper equipment for their needs. From the design stage, to the installation stage, to the system start up stage and beyond, AIR Inc. works hard to ensure that the baghouse works smoothly and effectively for the customer.

An example of the key milestone activities in the turn key project are listed below:

| Milestone | Description |

|---|---|

| Project Kick Off Meeting | A full understanding of the system requirements is assessed ensuring that customer and process needs will be met with the proposed baghouse system. |

| Engineering | After the system requirements are identified the AIR Inc. design team custom designs an emission control solution to fit the process’s needs. |

| Supply (Custom Fabrication & Supply of Parts) | •Baghouse system is fabricated. •System parts are sourced (examples: exhaust fan, jet pulse cleaning system, material handling equipment etc.). •Automation and electrical control systems are designed and built. |

| Mechanical and Electrical Installation | AIR Inc. has extensive experience with mechanical and electrical installation activities. |

| Start Up and Commissioning Services | Baghouse system is initiated for the first time. AIR Inc. will calibrate the baghouse system to ensure that it is operating to meet system requirements. |

| Post Project Services | AIR Inc. takes pride in the fact that their baghouse systems are built to operate for many years. To ensure that the systems operate long term AIR Inc. is available for trouble shooting issues and to help source replacements parts if required. |

Dust Collection System Analysis

With over 30 years of experience designing and supply dust collectors around the world, AIR Inc. has the hands on experience working with several different types of dust collectors. With this experience AIR Inc. has the ability to help trouble shooting or restore your old dust collectors back to operating condition.

With over 30 years of experience designing and supply dust collectors around the world, AIR Inc. has the hands on experience working with several different types of dust collectors. With this experience AIR Inc. has the ability to help trouble shooting or restore your old dust collectors back to operating condition.

Below you will find a few examples of services AIR Inc. can provide to improve and restore dust collection systems back to an effective state at your facility:

| Service | Description |

|---|---|

| Plant Dust Collection Study | Cataloguing dust collector systems at your plant along with an assessment of the effectiveness of dust collection equipment. Required and anticipated replacement parts will be identified for each dust collector allowing plant managers to plan maintenance budgets and shutdowns over the next few years. |

| Ineffective Dust Collection | Ineffective dust collection is usually a function of faulty equipment or improper ducting system balancing. AIR Inc. has extensive experience with the equipment associated with dust collectors along with air flow analysis and duct system balancing. With this experience, AIR Inc can pin point the source of the ineffective dust collection quickly and determine the solution to return your system to operating at full capacity. |

| Broken Parts or Replacement Parts | If your baghouse or dust collector has broken or faulty parts, AIR Inc. can provide a solution or the replacement parts required to fix it. |